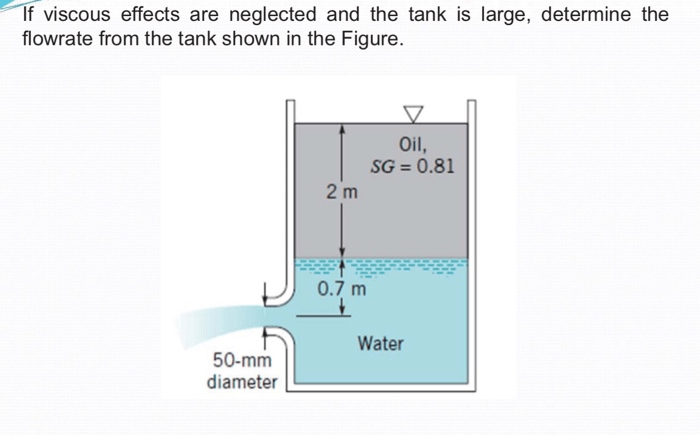

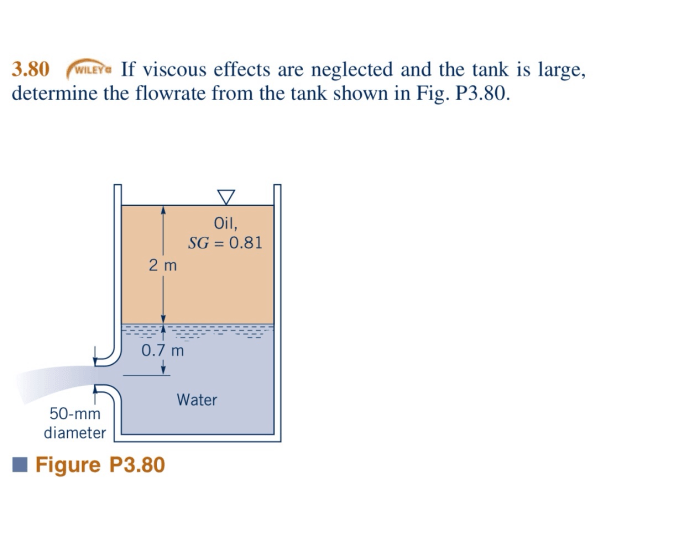

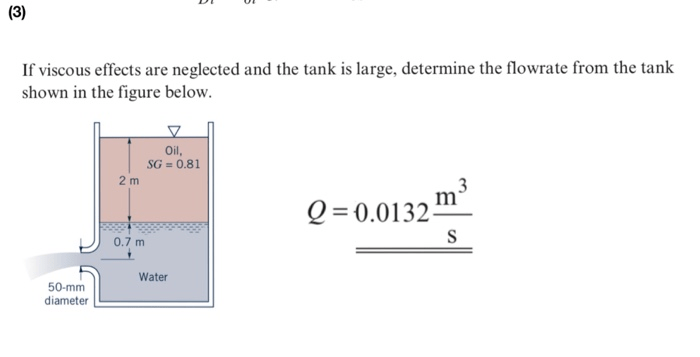

If viscous effects are neglected and the tank is large – When viscous effects are neglected and the tank is large, a simplified analysis can be performed. This approach assumes that the fluid’s viscosity has a negligible impact on the flow behavior, and the tank’s size ensures that boundary effects are minimal.

Understanding the implications and considerations associated with this assumption is crucial for accurate analysis and design.

This Artikel delves into the concept of viscous effects, the definition of a “large” tank, and the potential consequences of neglecting viscous effects. It also highlights factors to consider when making this assumption and provides a table comparing the effects of tank size on viscous effects.

1. Viscous Effects: If Viscous Effects Are Neglected And The Tank Is Large

Viscous effects refer to the resistance encountered by a fluid as it flows, caused by the interaction between its molecules. These effects can influence the flow patterns and pressure distribution within a fluid.

Neglecting viscous effects simplifies the analysis of fluid flow by assuming that the fluid behaves as an ideal fluid, which has no viscosity. This assumption can be valid in certain situations where the viscous forces are negligible compared to other forces acting on the fluid.

Examples of Situations Where Viscous Effects Can Be Neglected:

- High-speed flows, where inertial forces dominate viscous forces.

- Flows in large-diameter pipes or tanks, where the surface area is small relative to the volume.

- Flows with low viscosity fluids, such as water or air at low velocities.

2. Large Tank

A “large” tank is one where the viscous effects are negligible compared to other forces acting on the fluid. This typically occurs when the tank’s dimensions are large relative to the thickness of the fluid layer.

The size of the tank affects the validity of neglecting viscous effects because viscous forces are more significant in smaller tanks, where the surface area-to-volume ratio is larger.

Table Comparing the Effects of Tank Size on Viscous Effects:, If viscous effects are neglected and the tank is large

| Tank Size | Viscous Effects |

|---|---|

| Small | Significant |

| Medium | Moderate |

| Large | Negligible |

3. Implications of Neglecting Viscous Effects

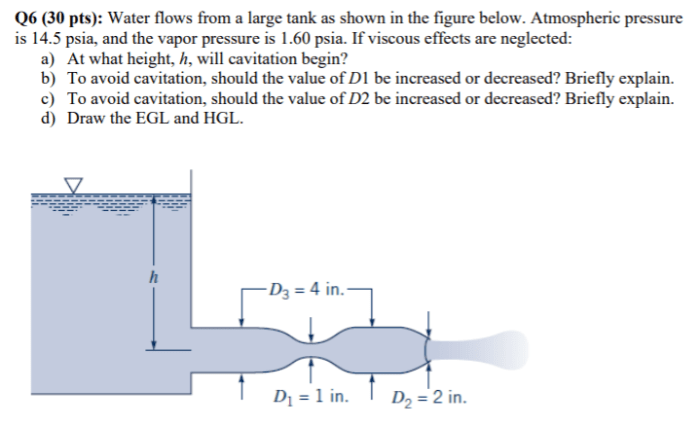

Neglecting viscous effects can have potential consequences on the accuracy of the analysis. It can lead to overestimation of flow rates and underestimation of pressure drops.

Limitations and Assumptions Associated with Neglecting Viscous Effects:

- The fluid must be Newtonian, with a constant viscosity.

- The flow must be laminar, without significant turbulence.

- The surface area-to-volume ratio must be small.

Examples of Scenarios Where Neglecting Viscous Effects May Lead to Inaccurate Results:

- Flows in small channels or pipes.

- Flows with non-Newtonian fluids, such as blood or polymer solutions.

- Flows with significant turbulence.

4. Considerations for Analysis

When deciding whether to neglect viscous effects, several factors should be considered:

- The size and geometry of the tank or channel.

- The viscosity of the fluid.

- The flow rate and velocity.

- The presence of turbulence.

Checklist or Decision Tree to Guide the Analysis Process:

- Determine the size of the tank or channel.

- Estimate the viscosity of the fluid.

- Calculate the flow rate and velocity.

- Assess the potential for turbulence.

- Make a decision based on the criteria discussed above.

Trade-Offs Involved in Neglecting Viscous Effects:

- Advantages:Simplifies the analysis and reduces computational costs.

- Disadvantages:May lead to inaccurate results in certain situations.

General Inquiries

What are viscous effects?

Viscous effects refer to the resistance to flow caused by the internal friction within a fluid.

How does the size of the tank affect viscous effects?

In a large tank, the ratio of surface area to volume decreases, reducing the influence of boundary effects and making viscous effects less significant.

What are the potential consequences of neglecting viscous effects?

Neglecting viscous effects can lead to inaccurate predictions of flow patterns, pressure distributions, and energy losses, especially in small tanks or systems with high viscosity fluids.